We are able to provide cutting and forming of metal materials for our customers. We mainly deal with laser and plasma cutting, bending and bending. We offer a full range of profiles and sheets according to customer requirements. Our firing center is located at the Holešov branch. We machine small parts on semi-automatic machines.

- CNC laser cutting machine NUKON PRO 315

NUKON, NF PRO 315 CNC laser cutting machine

Fiber laser for high quality, fast and accurate cutting, with the possibility of cutting reflective materialsSpecifications

cutting capacity: 3 kW fiber laser material – maximum thickness: ordinary steel 20 mm stainless steel 10 mm aluminium 8 mm cooper 5 mm brass 5 mm device dimensions: 8700 x 3000 x 2300 mm - CNC cutting center RUM 2500 P

CNC cutting center RUM 2500 P

We have expanded another fast and accurate solution for our clients in the field of plasma cutting of metallic materials.In addition, we now offer clients the cutting of pipes and holes in pipes in these parameters:

- tube diameter 50-600 mm

- tube length do 3 000 mm

- material thickness up to 20 mm

As standard, we offer plasma cutting of material on a CNC cutting center RUM 2500 P, which can handle:

- maximum burning size up to 2 100 x 6 000 mm

- divides standard steel to a thickness of 65 mm

- divides stainless steel steel up to a thickness of 50 mm

The plasma cutting method is suitable for cutting edges, contours, multiple cutting / using multiple torches), hole cutting, intermittent cutting, etc. It allows the use of a very high cutting speed depending on the material and thickness. In this way it is possible to cut almost all metal materials, the only limitation is the thickness of the material.

The CNC RUM 2500 P contains a cutting machine with double-sided guidance, equipped with powerful servo drives for fast and precise cutting. This machine is equipped with a Hypertherm HPR 260 plasma source.

The entire club center is loaded with a 2 ton hoist.

The programmer is able to transmit the entire firing plans via cable directly to the firing center and from a more distant place. These two workplaces are therefore able to work completely independently and independently.

- Press BAYKAL APHS 4100

Model APHS 4100 mm. Automated sheet metal bending. Electronic synchronization via proportional valves guarantees maximum bending accuracy.

Specifications

working length: 4 100 mm bending capacity: 300 t stroke: 320 mm table width: 280 mm device dimensions: 5100 x 1820 x 3200 mm - Press BAYKAL APHS 31120

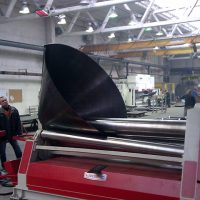

- Rolling machine APK 180

AKYAPAK hydraulic profile rolling machine

Model APK 180. Possibility of bending a whole range of steel profiles.

Specifications

bending options: brochure in PDF (CZ, 232 KB) device dimensions: 2400 x 2000 x 1695 mm - AHS 25 4-cylinder bending machine